Pourquoi les condensateurs sont le choix privilégié pour la compensation de puissance réactive

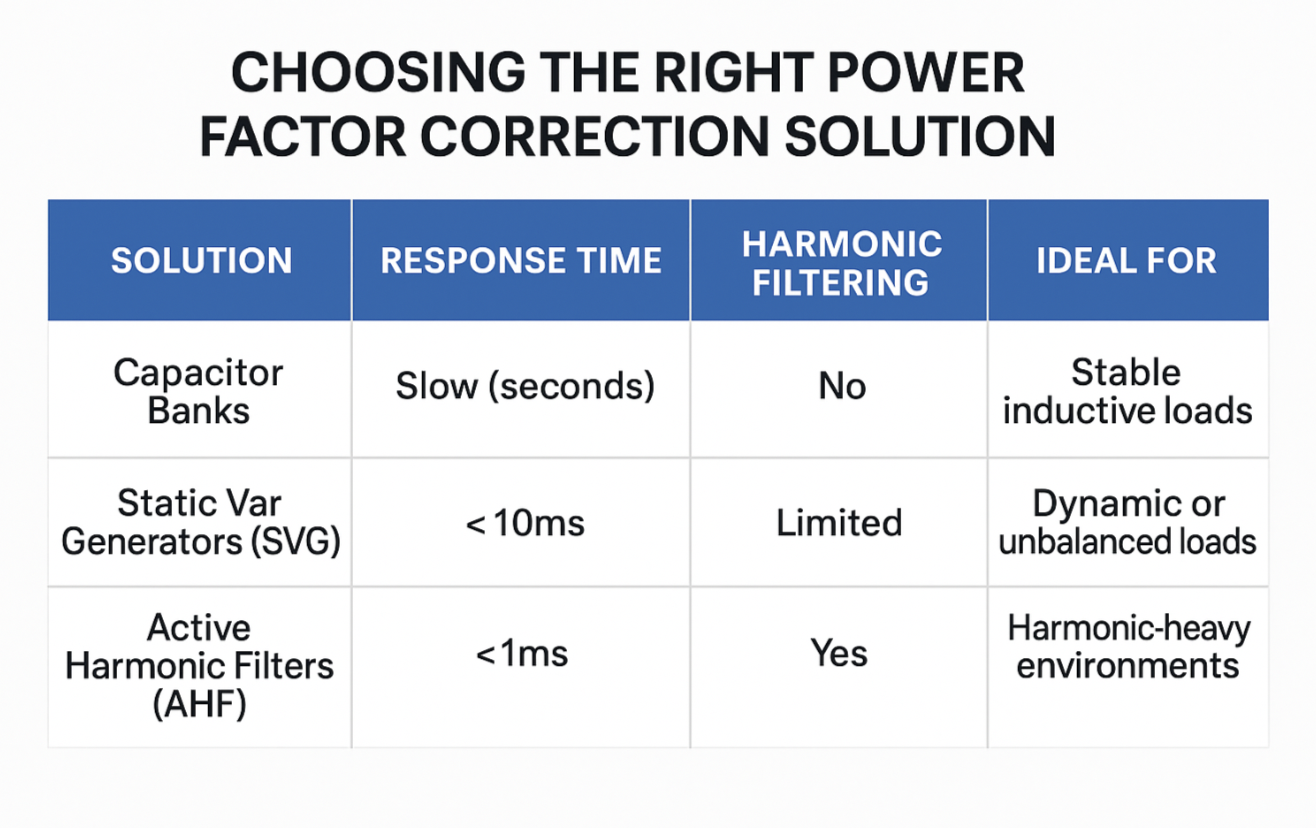

Lorsqu'il s'agit de compensation de puissance réactive basse tension, la conversation se réduit généralement à deux options : les batteries de condensateurs et les générateurs de tension statique.

Demandez autour de vous et vous entendrez probablement une raison courante pour laquelle les condensateurs restent populaires :

« Ils sont moins chers. »

C’est vrai, mais la véritable réponse est plus profonde.

Les batteries de condensateurs sont rentables, simples et éprouvées.

Investissement initial réduit

Installation rapide et facile

Besoins d'entretien minimes

Les condensateurs ne comportent aucun composant complexe : pas d'électronique de puissance, ni de système de refroidissement. Leur maintenance est simple et ne requiert pas de compétences très spécialisées.

Les SVG, en revanche, utilisent une électronique de puissance avancée et nécessitent une mise en service et une maintenance qualifiées. Leur coût de possession est plus élevé, incluant l'installation, les diagnostics et même les mises à jour du micrologiciel. Pour les installations à charges stables, cette complexité supplémentaire est souvent peu avantageuse.

Au-delà du prix, le comportement du système est important.

Les condensateurs sont idéaux pour charges stables — tels que les moteurs, les pompes, les compresseurs et les convoyeurs. Grâce à une commutation étagée et à un contrôle approprié, ils peuvent répondre à la plupart des besoins de compensation réactive dans ces environnements.

Cependant, pour charges changeantes rapidement ou irrégulières Les batteries de condensateurs peinent à suivre. C'est là que les SVG excellent. Elles offrent compensation précise et en temps réel qui s'adapte instantanément aux fluctuations de charge.

Pensez-y de cette façon :

Les condensateurs sont votre marteau fiable. Les SVG sont votre scalpel de précision.

Les condensateurs réagissent en quelques secondes, même équipés de systèmes de commutation intelligents. Pour de nombreuses applications, cela suffit. Mais dans les environnements où les variations de charge sont rapides, ces secondes peuvent provoquer des chutes de tension, des scintillements, voire des pénalités.

Les SVG répondent en millisecondes Cette vitesse est cruciale dans des secteurs tels que :

Ateliers de soudure

Systèmes d'ascenseurs

Lignes d'emboutissage de métaux

Opérations du four à arc

Dans ces cas, le retard du condensateur peut entraîner des problèmes de qualité de l'alimentation. Les SVG assurent la stabilité et la réactivité du système, même dans des conditions extrêmes.

Batteries de condensateurs sont sensibles à distorsion harmonique Dans les systèmes présentant des niveaux élevés d’harmoniques (généralement causés par des variateurs de fréquence, des onduleurs ou des redresseurs), les condensateurs peuvent aggraver le problème en créant une résonance.

Pour éviter cela, des réacteurs sont souvent ajoutés en série, mais cela augmente les coûts et la complexité.

Les SVG ne rencontrent pas ce problème. En tant que dispositifs actifs, ils suppriment naturellement les harmoniques de rang faible et améliorent la qualité de l'énergie, sans nécessiter de filtres supplémentaires. Si votre installation est soumise à un environnement électrique « sale », les SVG offrent une protection que les condensateurs ne peuvent pas offrir.

Cela dit, pour systèmes d'alimentation plus propres , les condensateurs font toujours le travail de manière efficace et économique.

Bien que les condensateurs restent la solution de choix pour de nombreuses applications, il existe des situations où les SVG ne sont pas seulement préférables, ils sont essentiels :

Les SVG stabilisent la tension et le facteur de puissance en temps réel, ce qui est idéal pour les processus dynamiques tels que le soudage à l'arc ou l'emboutissage.

Si vous devez maintenir un facteur de puissance supérieur à 0,99, les SVG fournissent la précision et le contrôle nécessaires pour éviter les pénalités de service public.

Dans les installations comportant de nombreux variateurs de fréquence ou charges non linéaires, les SVG filtrent les harmoniques nuisibles que les condensateurs pourraient amplifier.

Les installations solaires et éoliennes nécessitent une tension dynamique et un support de puissance réactive. Les SVG répondent parfaitement aux normes de conformité du réseau.

Les SVG peuvent corriger les déséquilibres entre les phases et stabiliser les tensions dans des conditions de réseau faibles ou instables.

Si vos opérations ne peuvent pas tolérer la nature progressive de la commutation des condensateurs, les SVG offrent une compensation fluide et continue.

Les condensateurs restent populaires non seulement parce qu'ils sont abordables, mais aussi parce qu'ils fonctionnent. fiable, éprouvé et efficace pour la grande majorité des scénarios de charge stable.

Cependant, SVG offrir précision, rapidité et flexibilité que les condensateurs ne peuvent pas égaler, en particulier dans les environnements exigeants ou en évolution rapide.

Chez YT Electric, nous sommes là pour vous aider à trouver la solution idéale. Que vous exploitiez une usine à charge constante ou que vous gériez un système industriel haute performance, nous pouvons analyser vos conditions d'alimentation et vous recommander la solution la plus adaptée : batteries de condensateurs, systèmes de stockage d'énergie à haute performance, voire une approche hybride.

Parlons-en

YT Electric est le plus grand fabricant OEM de câbles basse tension AHF et SVG, avec plus de 15 ans d'expérience. Tous ses produits sont certifiés ISO9001, CE et CQC, et sont appuyés par des rapports d'essais de type.

Pour plus d'informations sur la façon dont nos SVG peuvent aider à gérer les harmoniques et à améliorer la qualité de l'énergie :

contactez-nous au sales@yt-electric.com .

abonnez-vous à nous pour profiter des prix des événements et obtenir certains des meilleurs prix.

réseau ipv6 pris en charge

réseau ipv6 pris en charge